Automatic poultry cage wire mesh welding manufacture

Product Description

Automatic poultry cage wire mesh welding manufacture

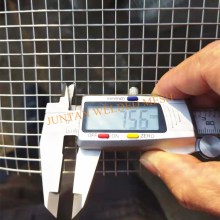

This is our new developed Chicken cage welding machine DP-AW-1200H (Pneumatic type). The welding speed can be up to a maximum of 130 times/min. It has the advantage of easier machine maintenance, fewer machine problems, easier to learn and operate, save power and consumption, less welding spark, etc. We also have mechanical type machine, the model is DP-AW-1200E

| Model | DP-AW-1200H | DP-AW-1500H | DP-AW-1600H |

| Wire diameter | 2-3.5mm/2-4mm | ||

| Longitude wire space | Mostly 50-200mm(If min.25*25mm, we can also design.) | ||

| Crosswire space | Min.25mm or smaller (PLC control) | ||

| Mesh width | Max.1200mm | Max.1500mm | Max.1600mm |

| Welding electrodes | 25pcs | 32pcs | 32pcs |

| Welding transformer | 125kva*3pcs | 125kva*4pcs | 125kva*4pcs |

| Longitude wire feeding | Form wire coils | ||

| Crosswire feeding | Pre-straightened&pre-cut(cross wire Feeder) | ||

| Welding speed | Max.130 times/min | ||

| Space needed | 12*5m | ||

| Machine weight | 3100kg | 3600kg | 3840kg |

| Pneumatic welding, each welding electrode is controlled by one SMC air cylinder. Electrodes 20*20*20mm can be used 6 sides. |

| Double cross wire feeders, can feed different lengths of cross wires. You can also choose a single cross wire feeder. The feeding speed can max .130pcs/min. |  |

| The edge cutter is controlled by two big SMC brand air cylinders on two sides, the cutting speed can match the welding speed. |

| Panasonic servo motor for pulling mesh, cross wire space can be adjusted by PLC. The pulling rack is the J&T brand, more accurate, less noise. |  |

| The mesh cutting is automatic, max.3m length. After cutting, the mesh can fall down automatically to the mesh stacking car. |

|  |

1. The cage bending machine is used to bend the top cage mesh and bottom cage mesh.

2. The edge Cutting Machine is used to cut the extra wires of the mesh side.

3. The door digging machine is used to cut the insider wires of the cage mesh to make a door.

4. C nail gun is used to connect the bottom cage mesh, top cage mesh, and partition mesh.

5. The electric cutter is used to cut the mesh manually.

6. The spot welding machine is used to weld the partition mesh, single spot or multi spots.

7. Wire straightening and cutting machine is used to straight and cut the wires.

Product Categories : Chicken cage welding machine

Premium Related Products